Choosing Cap Mold Materials: How to Get Maximum Durability in 2025

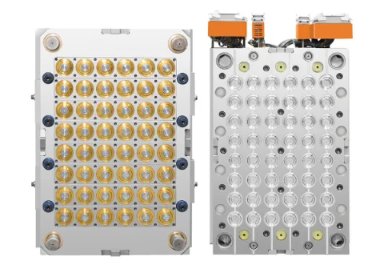

Making caps for bottles or jars means picking the right cap mold matters a lot. A tough cap mold saves cash on replacements, keeps production steady, and cuts downtime. The material you choose affects cycle times, cap quality, and how often you fix it. In 2025, factories are focusing on cap moulds, coatings, and upkeep tricks to get the most from their gear. Foshan Heyan Precision Mold Technology Co., Ltd. leads the pack with high-quality cap moulds and ring lifting molds for strict production needs. With years of know-how, their cap molds fill cavities evenly, resist wear, and handle hot runs for ages. Their team keeps molds exact, so production stays smooth. Check out Heyan. Their solutions help factories churn out caps without constant stops.

What Are The Most Common Cap Mold Materials?

Picking a cap mold material means balancing cost, toughness, and what your factory needs. A good cap mold keeps your line humming, stops flash, and lasts for thousands of runs without big fixes.

Steel Varieties For Cap Molds

Steel is the go-to for tough cap moulds. P20 steel is liked for its easy machining and strength for medium runs. H13 steel fights wear better and handles heat well, perfect for big runs or rough resins. S136 stainless steel stops rust, great for food or drink caps. The right steel choice cuts how often you polish or fix the mold. Think about your run size and resin type to pick smart.

Aluminum Cap Molds

Aluminum molds are light and cool fast, speeding up cycles. They’re used for test molds or small runs because they’re quick and cheap to make. But aluminum wears out faster than steel. For long runs, you’ll fix it more. Still, for short jobs, they’re a nice mix of speed and price.

Hybrid Or Coated Molds

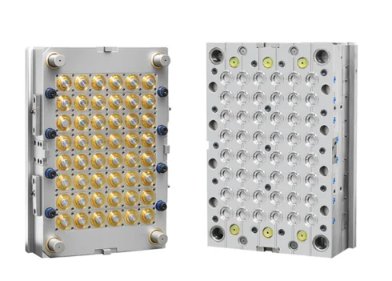

Coatings like nitriding, PVD, or chrome plating make steel or aluminum molds last longer. They fight scratches and rust from harsh resins. For multi-cavity cap moulds, coatings keep all cavities wearing evenly. This means caps stay the same shape and quality. Mixing a good base material with a coating gives the best bang for your buck.

How Material Properties Affect Durability

A cap mold’s traits shape how well it works. Strength, heat handling, and rust resistance decide how long it lasts and how good the caps are.

Heat Resistance And Thermal Fatigue

Fast cap-making heats and cools molds a lot. This can wear them out. H13 steel handles high heat without bending, unlike aluminum, which might warp after many runs. For quick cycles, heat-proof molds cut downtime and bad caps. For example, a mold running 10,000 caps daily needs strong heat resistance to stay sharp.

Wear And Abrasion Resistance

Molds face friction from hot plastic and constant opening. Softer materials get scratches or worn cavities, making uneven caps. Steel molds with coatings fight this wear. They keep caps steady and stop flash or weird shapes. A worn mold might need fixing every month, but a coated one could last a year.

Corrosion And Chemical Resistance

Resins or cleaning liquids can eat at molds. Stainless steel or coated molds handle these better, avoiding pits or damage. This is key for drink or makeup caps, where clean molds matter. For instance, a mold for soda caps needs rust-proof steel to stay safe and smooth.

Choosing The Right Material For Your Production Needs

The best cap mold material depends on your run size, resin, and how long you need it. Thinking about upkeep costs and lifespan saves money.

High-Volume Manufacturing

For big runs, tough steel like H13 or coated steel is best. Multi-cavity cap moulds need steady, heat-proof materials to fill all cavities evenly. These molds cut downtime and repairs, giving steady caps even after tens of thousands of runs. For example, a factory making 50,000 caps daily needs H13 to avoid constant fixes.

Small Batch Or Prototype Runs

Aluminum or softer steel works for test runs or small batches. These molds are fast and cheap to make, great for trying new cap designs. Speed beats long life here. A prototype mold for 1,000 caps can be aluminum to save cash, even if it wears quicker.

Maintenance Practices To Extend Mold Life

Even a great cap mold wears out without care. Cleaning often, checking for scratches, and storing right can make it last way longer. Modular molds are easy to fix. You can swap one cavity without stopping the whole line. Polishing cavities regularly keeps caps perfect and cuts bad ones. For example, a quick polish every 5,000 runs stops flash. Good mold maintenance pairs with tough materials to keep your cap mold rocking.

Future Trends In Cap Mold Materials?

Factories are trying new steel mixes, fancy coatings, and hybrid designs. Going green is big, with molds that use less power to make or run. Multi-cavity cap moulds with better cooling are popping up. New coatings promise longer life while keeping caps top-notch. Watching these trends helps you stay ahead in 2025.

Conclusion

Picking the right cap mold material is about smarts, cost, and planning. Steel gives the longest life, aluminum speeds things up, and coatings bridge the gap. With good mold maintenance and multi-cavity designs, you get steady, high-quality caps for thousands of runs. For factories aiming to cut downtime, trim scrap, and keep production smooth, tough cap moulds pay off fast, making your work predictable and efficient.

FAQ

Q1: Which type of steel lasts longest for cap molds?

A: H13 and coated steels handle heavy-duty production best. They resist wear and thermal stress effectively.

Q2: Can aluminum molds be used for high-volume production?

A: They’re lighter and faster to produce, but they wear out sooner than steel. For long runs, steel molds perform better.

Q3: In what way do coatings extend mold life?

A: Coatings protect against scratches and corrosion, helping cap molds stay durable during intensive production.

Q4: Does the resin material influence mold selection?

A: Absolutely. Abrasive or aggressive resins require tougher, coated molds to maintain cap quality and reduce wear.

Q5: How frequently should cap molds be inspected and cleaned?

A: Perform cleaning and checks after every production cycle to ensure molds remain in top condition and avoid downtime.