Top Injection Molding Equipment for Efficient Production in 2025

Running a factory today depends on trusty injection molding equipment. As competition gets tougher and material costs climb, every second saved on the line counts. You’ve got to balance speed with care, making sure each part hits high quality marks. Tiny slips in heat, pressure, or timing can cause bad parts, material waste, or pricey downtime. The push for trickier parts and tighter fits makes picking the right gear super important. New injection molding equipment comes with cool tools like real-time tracking, servo-driven motors, and auto controls. These keep production steady in big runs, cut power use, and trim waste, which matters a lot for greener manufacturing.

What Makes Injection Molding Equipment Reliable in 2025?

Choosing solid injection molding equipment isn’t just about grabbing a big-name brand. It’s about gear that runs non-stop, makes steady parts, and handles different materials without constant tweaks. Today’s machines come with digital screens that track heat, pressure, and cycle times. These let you spot issues early, so you avoid wasting materials.

Key Features of Modern Injection Molding Machines

Reliable equipment needs to be steady and exact. Servo-driven motors cut down on jerky hydraulic moves, and precise heat controls keep resin flowing smooth into cavities. Modern machines have easy screens and warn you about upkeep needs. This combo keeps your line running without big hiccups, especially when paired with good multi-cavity injection molds.

How Equipment Stability Reduces Production Waste

A steady machine makes multi-cavity injection molds work right. When cavities get even pressure and heat, walls stay uniform, so you get fewer bad parts. Over thousands of runs, this saves heaps of material and keeps costs low. Even tiny slips in heat or alignment can cause flash, warping, or tossed parts.

How Can Injection Molding Equipment Boost Production Efficiency?

Efficiency means fast work without losing quality. You need injection molding equipment that speeds up but still makes perfect parts every time. Upgrading to new gear can cut downtime and boost output, making your factory more profitable.

Faster Cycle Times without Compromising Quality

New machines handle cooling and injecting at the same time. This shortens cycles but keeps parts top-notch. Better mold clamping and timed ejectors also keep things steady, which matters a lot for small parts in big batches.

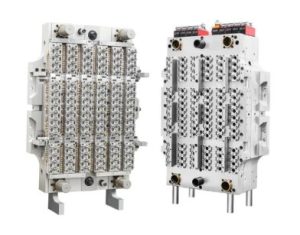

Multi-Cavity Molds for Higher Output

Using multi-cavity injection molds lets you make more parts per run. HEYAN molds, for instance, are built to fill all cavities evenly, so you don’t need to fiddle with settings much. This leads to a smoother line and less waste. See their multi-cavity mold options at [their website].

What Are the Energy-Saving Features in Modern Equipment?

Big production lines gulp loads of power. New injection molding equipment tackles this with smart designs that use less electricity and lose less heat.

Servo Motors and Optimized Hydraulic Systems

Servo motors give exact control over injecting and clamping, using less power than old hydraulic setups. Tweaked hydraulics waste less energy each cycle, so high-volume runs are kinder to the environment.

Intelligent Temperature and Pressure Control

Keeping heat and pressure steady improves parts and saves energy. It stops extra heating or cooling cycles. When your multi-cavity injection molds pair with machines that handle these well, you use less power and waste less material.

How Does Equipment Choice Affect Product Quality?

Picking the right injection molding equipment directly shapes how consistent and tough your products are. Matching machines with precise molds is key to delivering parts customers love.

Precise Mold Integration

A good machine-mold combo fills cavities right, avoids short shots, and keeps walls even. This matters for tricky shapes or high-cavity molds, where small errors can ruin parts.

Reducing Defects and Improving Wall Thickness Uniformity

Tiny changes in heat or speed can mess up walls, cause warping, or leave marks. Machines with tight controls, paired with well-made multi-cavity injection molds, keep quality steady across every run.

Future Trends in Injection Molding Equipment for 2025 and Beyond

The industry’s racing toward smarter, greener systems. Injection molding equipment will lean on predictive tools, energy-saving designs, and flexible materials.

Automation and Digitalization

Factories now use sensors to watch pressure, mold heat, and material flow live. Smart alerts catch issues before they make bad parts, cutting downtime and scrap.

Compatibility with Advanced Molds and Materials

New plastics, like bio-based or recycled resins, need careful heat and pressure control. Modern machines handle these, and precise multi-cavity injection molds keep parts perfect even with new materials.

Eco-Friendly Manufacturing Solutions

Cutting waste, saving power, and supporting green production are big deals. Machines that work with molds for even walls, fast cooling, and smart material use help make manufacturing kinder to the planet.

Custom Mold Solutions from HEYAN

Foshan Heyan Precision Mold Technology Co., Ltd. crafts high-quality multi-cavity injection molds that fit perfectly with modern injection molding equipment. Their designs ensure even cavity filling, steady wall thickness, and tough parts for non-stop production. These molds cut material waste, lower energy costs, and keep quality high. Check their offerings at [their website] or learn about the company [here]. Mold maintenance is easy with their modular designs, making cleaning and checks quick and trusty. Their skills help factories balance speed with steady quality.

Conclusion

Picking the best injection molding equipment is key for fast production, steady quality, and less waste. Pairing modern machines with precise multi-cavity injection molds boosts output, cuts scrap, and saves power. Good mold maintenance and process tweaks keep lines stable with fewer stops. For factories wanting better productivity and greener practices, teaming up with skilled mold makers like Foshan Heyan Precision Mold Technology Co., Ltd. brings both speed and reliability.

FAQ

Q1: What features should I look for in modern injection molding equipment?

A: Pick machines with exact heat and pressure controls, digital tracking, servo-driven motors, and support for high-cavity molds. These keep your line steady and cut waste.

Q2: How do multi-cavity molds improve production efficiency?

A: They make more parts per run, so you tweak less and save time. They also keep walls even across cavities for steady quality.

Q3: Can energy-saving features really reduce operating costs?

A: Yep. Servo motors, tweaked hydraulics, and smart cooling use less power and trim material waste, saving cash.

Q4: How does mold precision affect product quality?

A: Exact molds keep walls uniform, cut flaws, and make parts steady, even when you’re pumping out tons.

Q5: What trends should manufacturers watch for in 2025?

A: Look out for smart automation, upkeep alerts, new material support, and green production tricks.