Extrusion vs Injection Moulding: Which Process Makes Sense for Real Production Projects?

“extrusion vs injection moulding” sounds like a simple comparison, but real production projects rarely behave like a textbook. You are not choosing a process in a vacuum. You are choosing what kind of problems you will solve later, what your quality control will look like, and how predictable your output will be once the line runs for weeks instead of hours. This guide keeps the comparison practical, with one question in mind the whole time: which process makes sense for your part, your volumes, and your production reality?

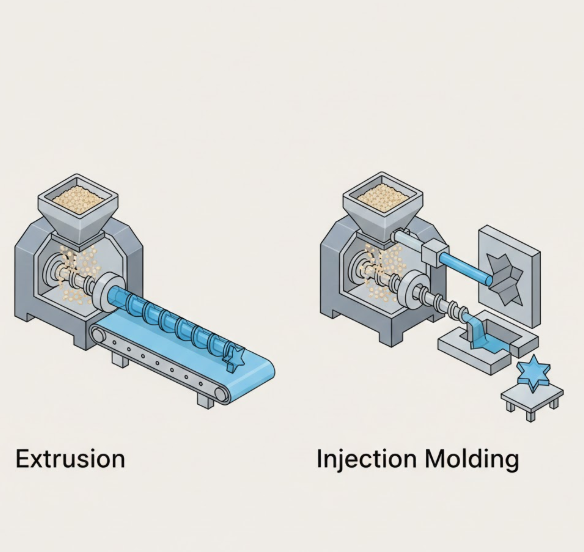

What Extrusion and Injection Moulding Are Designed to Do

Extrusion is built for continuity. You push melted plastic through a die to create a profile with a consistent cross-section, then cool it and cut it to length. If you need metres of the same shape, extrusion is hard to beat.

Injection moulding is built for discrete parts. You inject melted plastic into a closed mold cavity, pack it, cool it, and eject a finished component. If your part has complex geometry, functional features, or tight assembly requirements, injection moulding is usually the better tool.

Both processes are mature. The difference is not “which is better.” The difference is what each process makes easy, and what each process makes expensive.

For many profiles, the extrusion molding process stays competitive because output is continuous and quality checks can focus on profile stability.

Product Geometry and Shape Limitations

Geometry is the fastest way to narrow your choice, because each method has a natural comfort zone. For extrusion vs injection moulding, start by asking whether your part is mainly a long profile or a standalone 3D component.

When Extrusion Makes Sense

Extrusion fits products that are essentially a long profile. Typical matches include:

-

Tubes, channels, strips, trims

-

Profiles where the cross-section stays the same along the length

-

Parts that can be cut to different lengths without redesign

-

Designs that can accept drilling, punching, or light machining after extrusion

If your design can live with that workflow, extrusion molding can be the clean solution.

When Injection Moulding Is the Better Fit

Injection moulding makes sense when your part is three-dimensional and feature-rich. It is usually a better fit when you need:

-

Snap fits, ribs, bosses, threads, or undercuts

-

Local thickness changes and functional details in one shot

-

Repeatable interfaces for assembly, sealing, or alignment

-

Minimal secondary operations

A simple test helps: if you cannot describe your part as “a long profile,” extrusion starts to feel like a workaround. Workarounds can work, but they often cost more in secondary operations and inspection.

Production Volume and Repeatability Expectations

Volume is not just a number. It changes the economics and the risk profile of your choice.

Extrusion tends to scale smoothly. Once the die and cooling setup are stable, output is continuous. If demand rises, you often increase run time, adjust line speed, or add parallel capacity. Repeatability comes from steady-state conditions.

Injection moulding can also scale, but repeatability depends on cycle stability. Output comes in shots, not metres, so there are more points where variation can creep in: cycle-to-cycle changes, thermal balance, material lot shifts, and equipment behaviour over time. If you need high volumes of identical discrete parts, injection is still the right answer, but stability must be treated like a requirement, not a hope.

This is where many teams get surprised. They pick injection moulding for geometry, then discover the hard part is keeping results consistent once production runs long.

Tolerances, Consistency, and Quality Control

If your project involves assembly, sealing, or consistent performance, tolerances matter. Not “perfect numbers” on day one, but repeatable dimensions over time.

Extrusion tolerances are often achievable for profile dimensions and wall thickness, but they depend heavily on steady processing and cooling. Long profiles can warp, shrink unevenly, or vary with temperature shifts. If your design can tolerate those realities, extrusion may be fine. If your design depends on tight fits in multiple axes, extrusion quickly turns into a secondary-operation problem.

Injection moulding is usually stronger for tight dimensional control on complex parts. But in real production, consistency is a system problem. Small changes in thermal behaviour, pressure repeatability, or cooling can move dimensions enough to matter.

A quick decision table helps keep the extrusion vs injection moulding choice grounded:

| Decision Factor | Extrusion (Typical Strength) | Injection Moulding (Typical Strength) |

|---|---|---|

| Part shape | Constant cross-section profiles | Complex 3D geometry |

| Tight fits and functional interfaces | Harder without secondary ops | Stronger when process is stable |

| Output style | Continuous | Discrete cycles |

| Changeovers | Often quicker for profile families | Heavier planning, stronger control needed |

| Quality control focus | Profile stability | Process stability over time |

In plastic extrusion vs injection molding comparisons, the best answer usually comes from geometry, volume, and how much variation your project can tolerate.

Tooling, Changeovers, and Long-Term Cost Reality

Many comparisons stop at tooling cost, but that is only one piece. The real cost is what you pay to get stable output that meets your spec.

Extrusion tooling (dies) can be quicker to adjust and less complex than injection molds, depending on geometry. Changeovers can be faster, especially for product families that share similar profiles.

Injection moulding typically has higher upfront tooling investment because you are building a closed cavity that defines the full part. The payoff is part-level control. You can produce complex geometry in one cycle with fewer secondary operations, and you can keep feature repeatability high when the process is stable.

One practical reminder: long-term cost is rarely just die price or mold price. It is scrap, downtime, rework, sorting, and the labour spent chasing variation. A cheaper setup that drifts can cost more than a well-planned system that runs predictably.

Process Flexibility Over the Product Lifecycle

Process choice should match how your product will evolve.

In early development, extrusion can be forgiving for profile-based products. You can iterate on a die, test materials, and adjust downstream operations without rebuilding a full tool.

Injection moulding tends to win when the product stabilises and performance requirements rise. As you move from prototypes to long runs, the value of integrated features and consistent assembly behaviour becomes clearer. The trade-off is that injection needs stronger planning around repeatability, especially when volumes scale or multi-cavity production enters the picture.

If you expect frequent design changes, build that into your choice. If you expect a stable design with high volume and tight assembly needs, injection moulding often becomes the long-term fit.

Why Injection Moulding Requires System-Level Planning

This section is not here to “sell” injection moulding. It is here to explain why injection success in real production depends on more than selecting a machine and a mold.

Once injection moulding is selected, the biggest risk is not whether the part can be molded. It is whether the process stays stable across long runs, material lots, environmental shifts, and operator changes. That stability comes from coordination: thermal management, pressure consistency, cooling behaviour, and how auxiliary systems support repeatable cycles.

If you are planning an injection project with real production targets, a system view avoids expensive surprises. That is where system-level control in injection molding becomes relevant, because it treats injection as a complete production setup rather than a single equipment decision.

Conclusion

Extrusion and injection moulding are both strong choices when they match the job. Extrusion makes continuous profiles efficient and scalable, especially when the cross-section stays constant and secondary operations are acceptable. Injection moulding makes complex discrete parts practical, especially when assembly behaviour and feature repeatability matter.

The extrusion vs injection moulding decision is not a technical preference. It is a production strategy. Choose extrusion when your geometry is continuous and your quality needs fit profile control. Choose injection moulding when your part is three-dimensional and your project demands repeatable output. And if injection is the path, treat stability as part of the requirement from day one, because real production rewards planning more than quick fixes.

Precision Support for Injection Projects That Must Run Stable

HEYAN TECHNOLOGY (Foshan Heyan Precision Mold Technology Co., Ltd.) supports injection moulding projects where stable production matters as much as the mold itself. The focus stays on repeatable output: cavity balance, thermal control, cycle consistency, and the supporting systems that keep a line steady over long runs. If your project is moving from “it works in trials” to “it must hold spec for weeks,” this kind of system-oriented support helps you reduce tuning loops, cut scrap risk, and keep quality predictable when volumes scale.

FAQ

Q1: Is extrusion cheaper than injection moulding for most projects?

A: It depends on shape and finishing. Extrusion can be lower-cost for constant cross-section profiles, but secondary operations and inspection can change the total cost.

Q2: When is injection moulding the clear winner?

A: When the part is 3D, feature-rich, and must assemble or seal reliably. Injection moulding usually gives better control on complex geometry when the process is stable.

Q3: Can extrusion hit tight tolerances?

A: Yes for many profile dimensions, but results depend heavily on cooling and steady processing. Tight multi-axis fits usually require extra finishing or a different process.

Q4: Why do injection projects feel stable at first, then drift later?

A: Long runs expose thermal balance, cycle variation, material lot effects, and auxiliary system changes. Stability is a system outcome, not a one-time setup.

Q5: What is the best way to decide between extrusion vs injection moulding quickly?

A: Start with geometry. If it is a constant profile, extrusion is a natural fit. If it is a discrete 3D part with functional features, injection moulding is usually the better starting point, then plan for production stability early.