What Are the Most Cost-Effective PET Preform Solutions for Bottle Production?

“Cost-effective” sounds like a simple price question. In PET bottle work, it rarely is. The unit price of a pet preform matters, but the real money is often lost or saved through total production cost: cycle time, scrap rate, downtime, and how steadily your line runs week after week. The most cost-effective PET preform solutions are the ones that keep cost per bottle low while still giving you stable bottles at scale.

Why “Cost-Effective” Means More Than Preform Unit Price?

If you only compare quotes, you may miss the cost drivers that show up after the first long run. A preform that looks fine on day one can still push your line into a narrow process window, raise scrap rate, and create hidden manufacturing costs that are hard to spot in a spreadsheet.

Cost Per Bottle vs Cost Per Preform

Cost per preform is a purchasing number. Cost per bottle is an operating number. Once pet preform production starts, every small loss repeats thousands of times per hour. A 1% scrap rate on 10,000,000 preforms is 100,000 pieces that still consumed resin, electricity, labor, and time. That is why cost reduction in production usually comes from reducing waste and stabilizing output, not from chasing the lowest unit price.

Hidden Costs That Add Up Fast

The biggest “silent” costs are usually downtime and unstable cycle time. A short stop to clean vents, fix a cooling issue, or swap a worn insert can break the rhythm of injection molding production and the downstream blowing line. Even when the stop is only 30 minutes, the real cost includes missed pallets, extra changeovers, and the messy restart period where quality drifts. This is where production control and process control start to matter more than discounts.

Lightweight PET Preforms That Still Run Stable

Lightweighting is one of the most direct ways to lower manufacturing costs, but only when the preform still runs smoothly and the final bottle stays strong. “Lighter” is not automatically “cheaper” if it creates a quality fight on the line.

Why Preform Weight Is the Biggest Cost Lever

Preform weight is straight material usage. If you cut 0.5 g from a preform and run 10,000,000 bottles, that is 5,000 kg less PET used. That is real. It also lowers handling weight and can reduce energy consumption in heating, depending on your setup.

But preform weight cannot be treated as a single number. The wall thickness distribution has to support the bottle shape and top load. If the weight drops but the material distribution is wrong, you may see thin shoulders, soft panels, or base instability.

When Lightweighting Raises Total Production Cost

Lightweight PET preforms can push you into a tight process window. A small oven change, a small preform variation, or a small cooling shift can start a defect pattern. The result is more rejects, more rework, more checks, and sometimes slower settings just to keep bottles acceptable. The goal is lowering production costs, not winning a “lightest preform” contest.

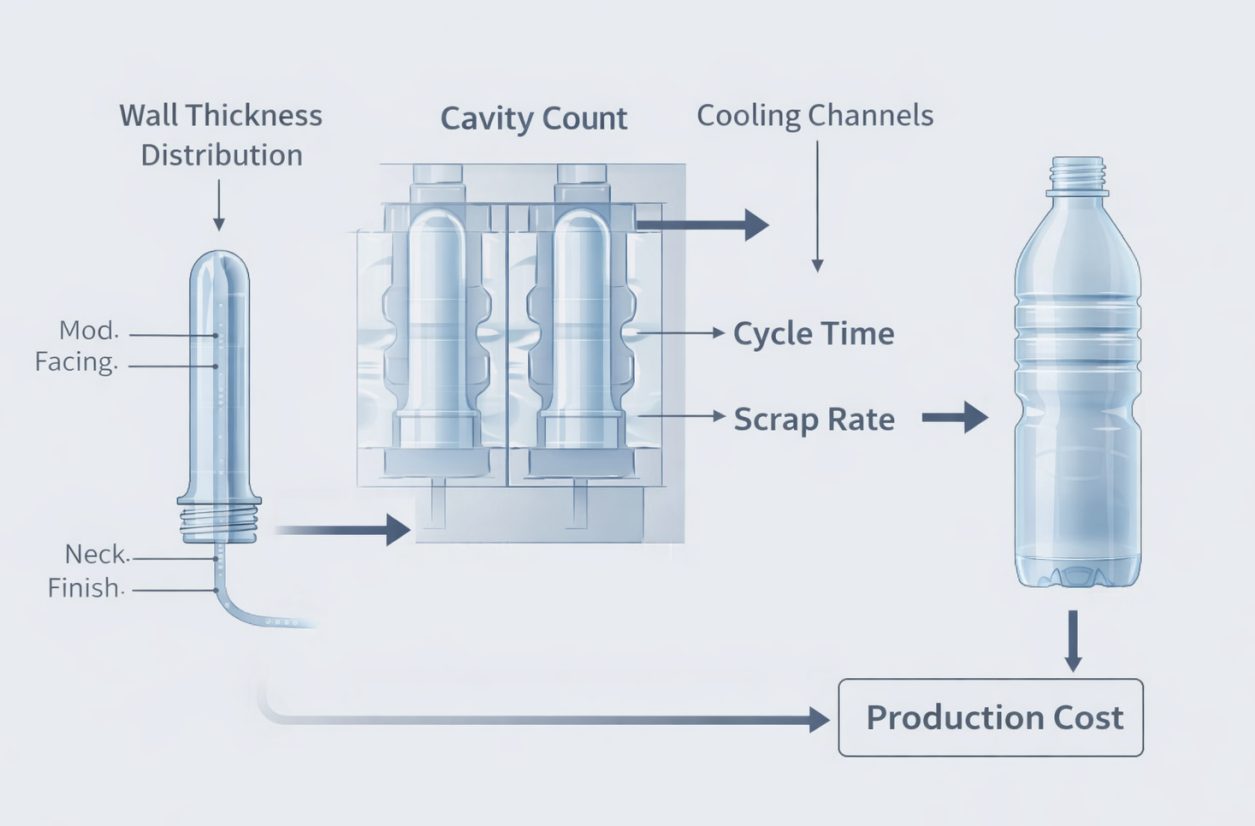

High-Efficiency Preform Mould Design and Cavity Utilization

A lot of “cost-effective” wins are decided inside the preform mould, before the first preform drops. The design choices in a pet preform mold affect cycle time, cavity consistency, maintenance cost, and how stable your injection molding technology is under daily production stress.

Cavity Count vs Real Output

Higher cavity count can reduce cost per preform, but only when all cavities behave the same. A 72-cavity preform mold that produces uneven parts is not really 72 cavities. It is a high-maintenance system that forces more sorting and more downtime.

Look at cavity consistency over long runs. If one cavity drifts in weight, neck finish, or gate quality, it becomes a constant source of scrap and line slowdowns. In practice, the “most cost-effective PET preform solutions” are often the ones that keep all cavities close in behavior, not the ones with the highest cavity count on paper.

Cooling Design and Cycle Time Reduction

Cycle time is a direct cost lever, but it is tied to cooling. A good mould cooling system keeps temperature even across cavities and across plates. When cooling channels are well designed and easy to keep clean, you can hold stable cycle time without pushing the process too hard.

On the other hand, poor cooling layout creates hot spots and slow spots. Then injection tooling has to compensate with longer cooling time, more conservative settings, or frequent stops to chase quality. That is not production efficiency. It is cost creeping in, one small decision at a time.

Lower Scrap Rate Through Better Preform Consistency

Scrap is not only bad parts. Scrap is lost time, lost attention, and usually a sign that your process is living too close to the edge. If your goal is production cost savings, scrap rate deserves a serious look.

How Preform Geometry Drives Scrap Rate

Preform geometry decides how the material flows during blowing. L/T ratio, wall thickness distribution, and the shape around the neck support ring all influence stretch behavior. If the geometry is off, you may see whitening, haze, uneven walls, or random weak areas after blowing.

Neck finish accuracy is another common cost trigger. If threads, sealing surfaces, or support ring geometry are inconsistent, capping problems show up later. Those problems do not stay “small.” They become customer claims, returns, and wasted production time.

Why Stable Tooling Matters More Than “Perfect” Samples

A preform can look perfect during a short trial and still fail in real production. What matters is how the mould holds dimensional stability after thousands of cycles, after temperature swings, and after normal wear. That is where good injection moulding process control helps, but control cannot fix a tool that drifts.

It is worth asking how the tool is built to stay stable, how wear parts are managed, and how quickly you can restore performance when something starts to drift.

Maintenance, Downtime, and Long-Term Operating Cost

The lowest quote can become the highest cost when maintenance is hard and downtime becomes routine. Long-term operating cost is where many projects quietly win or lose.

Downtime Is Often the Most Expensive Line Item

Downtime is not only lost output. It breaks your scheduling, adds overtime, and pushes rushed decisions. In many plants, the restart period after a stop creates extra scrap and extra checks. That is why “ways to reduce manufacturing costs” often look boring on paper: better cleaning routines, easier access to parts, and fewer unplanned stops.

What “Service-Friendly” Tooling Looks Like

Service-friendly preform mould design means wear parts are accessible, replacement is predictable, and small issues do not force a full teardown. Clear part standards, sensible spare parts planning, and practical maintenance guidance all reduce maintenance cost. This also supports better production systems, because your line can follow a repeatable routine instead of firefighting.

When Integrated Preform Solutions Make Sense

Some projects do fine with separate suppliers for different pieces. Others gain real value from integrated PET preform solutions, especially when scale and stability matter.

When injection molding process settings, mould cooling system behavior, and preform geometry are treated as one system, you can reach stable output faster and hold it longer. That improves production control and lowers total production cost over time. It also reduces the “it is not my problem” loop that appears when too many parties own too many small pieces of the chain.

Conclusion

The most cost-effective PET preform solutions for bottle production are not defined by a single number. They come from stable pet preform production with the right preform weight, consistent preform geometry, reliable cavity consistency, and a mould cooling system that supports fast, repeatable cycle time. Lower scrap rate, less downtime, and manageable maintenance cost are where reduce production costs becomes real, not just a promise. If you evaluate PET preform cost through total production cost and cost per bottle, the best choice usually becomes clearer. For plants evaluating PET preform solutions for bottle production, reviewing cost drivers from mould design to long-term operation is often more effective than focusing on unit price alone.

Where Cost Control Meets Real PET Output

HEYAN TECHNOLOGY (Foshan Heyan Precision Mold Technology Co., Ltd.) is built around one idea: stable PET production comes from stable tooling and repeatable engineering decisions. Based in Shishan Town, Nanhai District, Foshan, the team integrates R&D, engineering, production, and after-sales support for PET packaging programs. The core scope covers preform mould, bottle blowing mould, cap mould, and complete line supporting programs, so you can align preform design, mould cooling system layout, and downstream bottle requirements as one plan.

With 15+ years of manufacturing experience, a 5,000+ m² facility, 150+ devices, and 80+ talents, HEYAN TECHNOLOGY supports projects that care about cycle time stability, cavity consistency, and long-term operation, not just “first samples.” If you are comparing PET preform solutions for bottle production, this is the kind of supplier that talks in practical terms: scrap rate drivers, mould wear points, spare parts planning, and how to keep output steady when the line runs for weeks.

FAQ

Q1: What makes cost-effective PET preform solutions different from simply buying cheaper preforms?

A: Cost-effective PET preform solutions lower total production cost, not just PET preform cost. You look at cost per bottle, cycle time drift, scrap rate, downtime, and long-run cavity consistency. Cheap parts that shrink your process window often raise manufacturing costs later.

Q2: How can you tell if your PET preform solutions are truly lowering production costs?

A: Track cost per preform vs cost per bottle. If scrap rate drops, cycle time holds steady, and production efficiency improves across weeks of pet preform production, you are seeing real production cost savings and cost reduction in production.

Q3: Is lightweight PET preforms design always the best way to reduce production costs?

A: Not always. Lower preform weight saves resin, but only if wall thickness distribution still supports the bottle. If lightweighting tightens the process window and raises scrap rate, you end up lowering production costs on paper but paying more in rejects and downtime.

Q4: What should you check first in a pet preform mold when cycle time or scrap rate gets worse?

A: Start with the mould cooling system and cavity consistency. Cooling imbalance is a common trigger for longer cycle time, weight variation, and dimensional stability issues. Then review mould wear areas, process control settings, and spare parts condition before you chase injection molding process parameters.

Q5: Where does “pet injection molding” fit into ways to reduce manufacturing costs for bottle plants?

A: Pet injection molding affects the entire chain. Better injection molding technology and injection tooling choices can improve preform geometry, reduce variation across cavity count, and cut rejects downstream. In many manufacturing systems, the biggest savings come from steady production control, not aggressive settings that push equipment into frequent stops.