PET Preform Mold Cost 2026 China vs. Europe Price Analysis

It is the first question every procurement manager asks, and often the hardest to get a straight answer for: “How much should a PET preform mold actually cost?”

As we head into 2026, the cost scene for molds has changed. The space between European exactness and Chinese making skills is smaller than before. But the price gap stays large. For a plant owner, dealing with these offers can feel like stepping through a danger zone. One seller gives a 48 cavity preform mold for $40,000. Another asks $120,000 for what seems like the same details.

This guide explains just where your cash goes. It looks at the true costs of making in China against Europe. And it aids you spot which details really affect your Return on Investment (ROI).

The Three Technical Factors That Dictate Price

A generic quote for a “PET mold” is useless without the technical details. When you receive a proposal, the price tag is usually driven by three specific physical attributes: the steel, the injection system, and the cavity count.

1. Steel Selection and Hardness

The steel used for the core, cavity, and neck ring is the single biggest material cost. It determines whether your mold lasts for 2 million shots or 10 million.

- S136 (Stavax):This is the industry standard for high-volume production. It is a stainless steel that resists corrosion—critical if your facility operates in humid conditions or if you store molds for long periods. It polishes to a mirror finish, ensuring the preform surface is flawless.

- 2316 / P20:These are softer, cheaper steels. They are fine for short runs or prototype molds but will suffer from wear quickly.

Choosing the right steel is not just about the initial bill; it is about avoiding defects later. Cheap steel wears down, leading to issues like preform flashing which requires frequent, expensive downtime to fix.

2. The Hot Runner and Valve Gate System

The hot runner is the engine of the mold. In 2026, serious manufacturers have largely moved away from thermal gates and toward the valve gate system.

- Valve Gate:A physical pin closes the gate after injection. This leaves a clean bottom on the preform with no “tail” to trim, saving labor and resin.

- Self-Lock Structure:High-end molds feature a self-lock structure between the core and cavity. This ensures the two halves align perfectly every single time the mold closes, preventing eccentricity.

If a supplier’s price seems impossibly low, check the hot runner brand. Top-tier brands (like Husky or Mold-Master) cost a premium. However, a high-quality local brand often delivers 95% of the performance for half the cost, provided the engineering behind it is sound.

3. Cavity Count and Engineering Complexity

Price does not scale in a straight line. A 48 cavity preform mold is not simply twice the price of a 24-cavity version. As you add cavities, the challenge of balancing the plastic flow increases. The manifold design must be precise to ensure the preform in Cavity 1 fills at the exact same rate as the preform in Cavity 48.

This engineering time adds to the overhead. While high-performance multi-cavity injection molds cost more upfront, they drastically reduce your per-unit production cost.

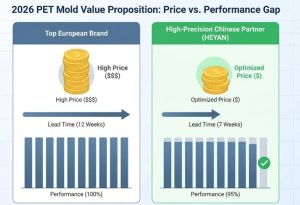

China vs. Europe: The 2026 Strategic Price Gap

For decades, European manufacturers (Switzerland, Canada, Germany) held a monopoly on precision. If you wanted a fast cycle time, you paid European prices. That reality has changed.

Top-tier Chinese manufacturers now use the same Mazak and Makino CNC machines as their European counterparts. The difference lies in overheads, labor rates, and brand premiums.

Here is a realistic look at the price ranges you will encounter in the current market for a standard setup:

|

Feature / Component |

Top European Manufacturer |

High-Precision Chinese Manufacturer (e.g., HEYAN) |

|

48-Cavity Mold Base |

$120,000 – $160,000 |

$40,000 – $60,000 |

|

Hot Runner Brand |

Mold-Master / Husky (Standard) |

High-End Local / Yudo (Optional) |

|

Steel Grade |

S136 (European Origin) |

S136 (China/Sweden Assorted) |

|

Lead Time |

10 – 14 Weeks |

6 – 9 Weeks |

|

Typical Cycle Time |

9 – 11 Seconds |

10 – 13 Seconds |

|

ROI Period |

18 – 24 Months |

6 – 9 Months |

For 90% of bottle projects, the China pet preform mold route offers a significantly faster payback period without sacrificing the physical quality of the bottle.

Compatibility with Global Machine Brands

A common fear for buyers is integration. If you have invested millions in machines from top pet preform injection moulding machine manufacturers (like Husky, Netstal, or HyPET), you might worry that a third-party mold won’t fit.

This is rarely an issue with professional mold makers. The interface between the mold and the machine is standardized.

- The Platen:The mold base is custom-machined to fit the tie-bar spacing of your specific machine model.

- Connections:Water manifolds, air plugs, and electrical connectors (hot runner controllers) are built to match your existing setup.

You do not need to buy the mold from the machine maker. In fact, separating these purchases is a common strategy to lower capital expenditure. Just ensure your mold supplier asks for the specific machine drawings before design begins.

The Hidden Math: Cycle Time and Resin Cost

The purchase price is a one-time expense. The mold cycle time is a cost you pay every minute the machine runs.

Consider the math of efficiency. If you run a 24-hour production line:

- Mold A (Budget Design):Runs at 16 seconds.

- Mold B (Optimized Cooling):Runs at 13 seconds.

Mold B is roughly 20% faster. That means 20% more bottles per day, with the same electricity and labor cost. Over a single year, the profit from that extra production usually exceeds the total cost of the mold itself.

Furthermore, a precise mold allows for consistent wall thickness. If a mold is imprecise, you often have to inject more plastic just to meet the minimum thickness requirements, wasting expensive material. To lower your final pet bottle preform price, you need a mold that allows you to run at the minimum safe weight, shot after shot.

Also, consider maintenance. A robust pet preform mould (spelled mold in the US) needs less attention. Following practical maintenance strategies is easier when the mold is built with accessible components and standardized parts.

Conclusion: Value Engineering is the Winner in 2026

The days of blindly choosing between “expensive European” and “cheap Chinese” are over. The market in 2026 demands a smarter approach.

If you buy the cheapest mold available, you are not saving money; you are simply moving the cost from the “Capital Expenditure” column to the “Maintenance and Scrap” column. A mold that is $10,000 cheaper but runs 3 seconds slower will cost you vastly more in lost productivity over its lifetime.

Your goal should be Value Engineering: finding a supplier who uses genuine S136 steel and reliable valve gate technology, but operates with a lean overhead structure. By focusing on the pet bottle preform price (your final production cost) rather than just the sticker price of the tool, you build a production line that is both profitable and resilient.

The High-Precision Alternative in Foshan

When looking for a balance between European performance and Chinese value, Foshan Heyan Precision Mold Technology Co., Ltd. (HEYAN TECHNOLOGY) stands out as a specialized partner. Located in Foshan, a global hub for manufacturing, this company has moved beyond the generalist approach to focus strictly on PET preform molds.

HEYAN is not just a machine shop; it is an engineering firm that tackles the specific pain points of bottle producers. They utilize advanced self-lock structures and proprietary valve gate systems to solve the eccentricity and flash issues that plague cheaper molds. Their facility is equipped to handle everything from 1-cavity prototypes to high-volume 48 cavity preform molds, ensuring compatibility with major international machine brands.

What distinguishes HEYAN is the rigorous testing protocol. Before a mold leaves the factory, it undergoes extensive cycle testing to verify cooling efficiency and dimensional stability. For buyers who need a mold life warranty that means something, HEYAN provides the technical documentation and spare parts support to keep production running for years, not just months.

FAQ: Common Questions on Mold Buying

Q1: How long can I expect a high-quality PET preform mold to last?

A: With proper maintenance and the use of S136 steel, a quality mold should last for at least 3 to 5 million shots. The mold life warranty usually covers the main stack components, while wear parts like O-rings need regular changing.

Q2: Does the mold price include the hot runner controller?

A: Usually, the quote is for the mold and the hot runner manifold inside it. The external temperature controller is often a separate line item. If you already have a controller that is compatible, you might not need a new one, but always double-check the pin connectors.

Q3: Can you make a mold that produces two different neck finishes?

A: Technically yes, by using interchangeable core/cavity inserts, but it is not recommended for high-volume production. Changing inserts takes time and wears out the fitting surfaces. It is usually more efficient to have dedicated molds for different neck finishes.

Q4: How does the cooling system affect the price?

A: A standard cooling design is cheaper to machine but slower to cool. An optimized design (often involving conformal cooling or complex water channels) costs more to manufacture but significantly reduces the mold cycle time. For mass production, the optimized cooling pays for itself very quickly.

Q5: What information do I need to get an accurate quote?

A: You need to provide the preform drawing (or the bottle design so the preform can be engineered), the required neck finish standard (e.g., PCO 1881, 30/25), the number of cavities you want, and the model of the injection machine you will use.

Still have questions about your specific project requirements?

Contact the engineering team at HEYAN to discuss your production goals.