How to Achieve Consistent Cavity Quality in Multi-Cavity Injection Molding

When you shift from a few cavities to a high-output mold, the real challenge isn’t the cycle time. It’s how to keep every cavity producing parts that look and measure the same. In multi cavity injection molding, a small drift in fill time, temperature, or steel details often grows into larger variation across all cavities. If you’ve seen good parts from one cavity and borderline parts from another, you’ve already met the problem this article aims to solve: achieving consistent cavity quality that holds up during long production runs.

What Does Consistent Cavity Quality Mean

Consistent cavity quality means each cavity produces parts with similar dimensions, appearance, and function. You want dimensional accuracy and stable geometric behavior across the entire mold, not just a few good cavities. For most plastic parts, injection molding tolerances around ±0.1 mm are common, while critical features sometimes require tighter bands. These numbers matter more when you run many cavities because cavity-to-cavity variation can double or triple the effective drift.

Before thinking about tools or settings, treat consistency as something that shows up in assembly. If threads, snaps, or sealing zones vary by cavity, even small offsets turn into leaks, loose fits, or complaints. Consistency is the outcome, not just a measurement.

Dimensional, Cosmetic, And Functional Targets

Dimensional consistency covers length, width, straightness, and roundness. Cosmetic consistency shows through in gloss, sink, and flash. Functional consistency is what your customer feels when parts assemble: a cap that fits the same from any cavity or a hinge that clicks with similar force.

Once you improve cavity filling consistency, these three areas often improve together. It becomes easier to hold injection molding precision, and you stop seeing that pattern where the “same family mold” produces parts that behave completely differently.

How Variation Shows up in Scrap

Variation usually shows up first in part weight. Heavier cavities may be overpacked, while lighter ones may be close to short-shot conditions. If this spreads, dimensional drift becomes visible, and sorting becomes costly. Scrap often comes from only a few cavities, a sign that deeper imbalance exists.

Root Causes of Cavity-To-Cavity Variation

Consistent output depends on balanced flow, controlled heat, and repeatable process behavior. Studies on multi cavity injection molding show that flow, shear balance, and cooling variation are the root causes of uneven performance across cavities.

Understanding where variation comes from helps you focus your time where it matters.

Runner And Gate Imbalance

Runner balance problems sit at the top of most lists. Small differences in flow length, gate size, or hot runner settings lead to fill imbalance. This pushes some cavities ahead while others lag. Specialists often use the terms shear imbalance and steel imbalance to describe whether flow issues come from geometry or from how the resin is stressed in each branch.

A balanced runner system does more than improve filling. It helps reduce the pressure drop differences that later influence shrinkage and injection molding tolerances.

Cooling And Thermal Gradients

Cooling system design plays a big part in cavity-to-cavity variation. Thermal gradients, uneven channel flow, and hot spots lead to different shrinkage rates and create warpage tendencies that no process tweak can fully smooth out. Research has shown that cooling uniformity is just as important as balanced flow.

Machine settings can only compensate for so much. If the cooling layout is inconsistent, expect dimensions to wander.

Mold And Cooling Strategies for Stable Cavity Quality

Good outcomes begin with design. Symmetrical layouts, equal flow paths, and solid steel work make multi-cavity mold design strategies effective. A well-built multi cavity injection mold creates fewer headaches during process tuning.

Layout, Gates, And Steel Quality

You get better results when cavity layout and gating strategy keep flow paths similar. Differences in gate type, gate size, and part thickness push cavities into different flow groups and create predictable imbalance. Fixing these during design is easier than chasing them on the machine.

Steel details also matter. Poor venting or rough EDM texture changes how air escapes and how the melt fronts meet. Over time, cavity wear may require cavity rework to restore long-term stability.

Cooling System Design And Thermal Control

Cooling system design shapes the final quality more than many expect. Channel layout, pressure drop, and flow rate all influence cavity temperature variation. With better cooling, you cut shrink differences and keep injection molding precision closer to your targets.

If cooling is weak in one region, even tight tolerance injection molding becomes harder than it should be.

Process Control And Cavity-Level Monitoring

Once the mold is built, process control decides whether the tool performs at its best. Basic short-shot analysis, fill time checks, and pressure curves help you confirm cavity balance before full production.

Fill Studies And Practical Adjustments

Short-shot studies reveal which cavities fill first and which fall behind. Adjustments to injection speed, melt temperature, or packing pressure often help bring cavity groups together without touching steel. It’s a simple way to stabilize cavity-level process control during daily work.

Keeping a close eye on part weight and one or two critical dimensions helps catch early drift long before scrap builds up.

Sensors And Key Data on the Floor

Some factories add in-mold pressure sensors to watch cavity pressure curve patterns. Research shows that these sensors make it easier to control multi cavity injection molding and react earlier to cavity imbalance.

You do not need sensors in every cavity. Even a few channels can help keep injection molding tolerances in the right range for precision injection molding.

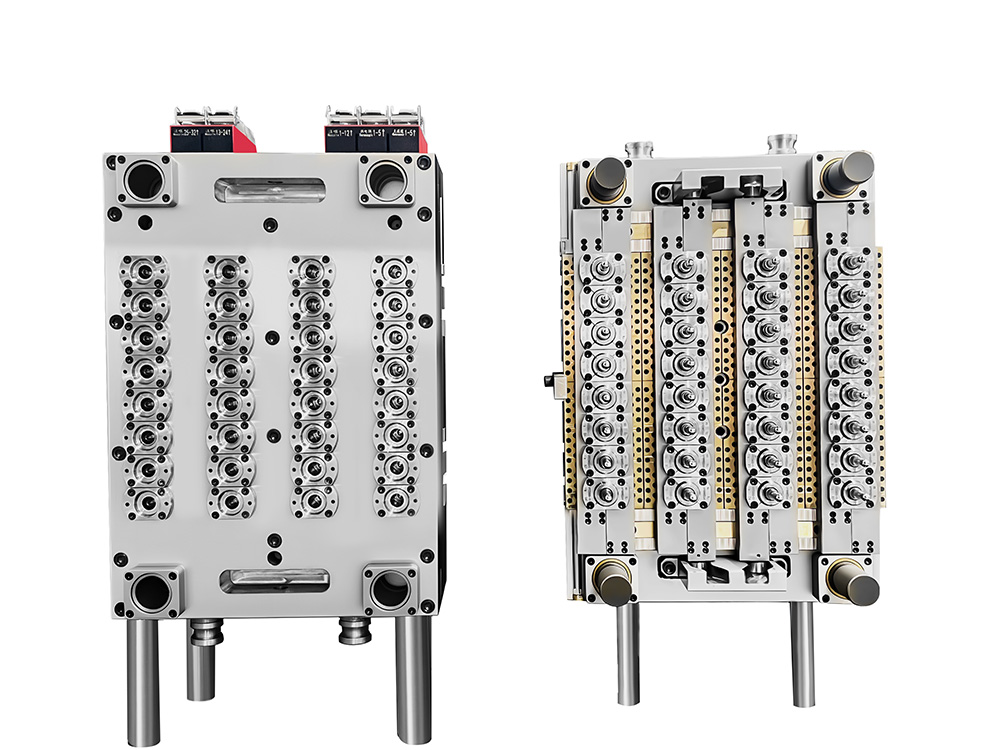

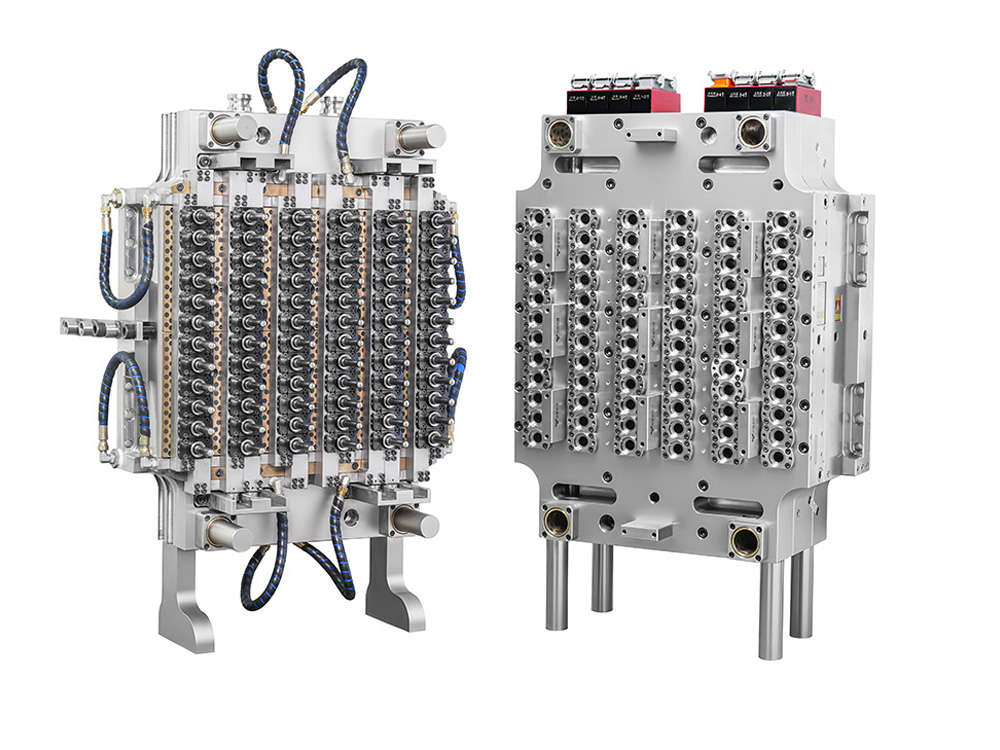

Introducing HEYAN TECHNOLOGY

HEYAN TECHNOLOGY (Foshan Heyan Precision Mold Technology Co., Ltd.) focuses on multi-cavity tooling that keeps cavity-to-cavity variation low during long production runs. The company uses mold flow analysis, balanced layouts, and precise steel machining to help customers achieve consistent cavity quality from day one. Their projects often involve high-output molds where cooling system design and runner balance shape success far more than isolated tweaks.

For clients who need reliable molds for demanding applications, the team also supports tight tolerance injection molding through custom gating strategies and practical maintenance planning. The aim is to keep molds running smoothly, with less drift and fewer adjustments required during peak production.

FAQ

Q1: Why does cavity-to-cavity variation happen even with a new mold?

A: Small differences in flow, cooling, and steel machining add up during multi cavity injection molding, creating measurable variation even in new tools.

Q2: What is the quickest way to spot imbalance?

A: Run a short-shot or fill study. You’ll often see which cavities lead or lag by comparing fill patterns and early part weights.

Q3: How much does cooling affect consistency?

A: A lot. Cooling drives shrinkage and temperature gradients, and these control both dimensions and stability.

Q4: Do you need sensors in every cavity?

A: No. A few well-placed pressure sensors provide enough data to catch early drift and improve overall consistency.

Q5: When should you consider reworking a cavity?

A: If one cavity consistently needs special settings or fails more often, it may be a steel issue that requires repair rather than process tuning.