How to Customize PET Preform Solutions for Complex Bottle Shapes

Complex bottle shapes look great on a shelf. They can also turn a stable line into a daily guessing game. When you move beyond round bottles into ovals, deep panels, sharp transitions, or heavy embossing, “standard” preforms often stop behaving like standard parts. The bottle may still form, but the process window gets tight, scrap rate climbs, and production consistency becomes hard to hold across shifts.

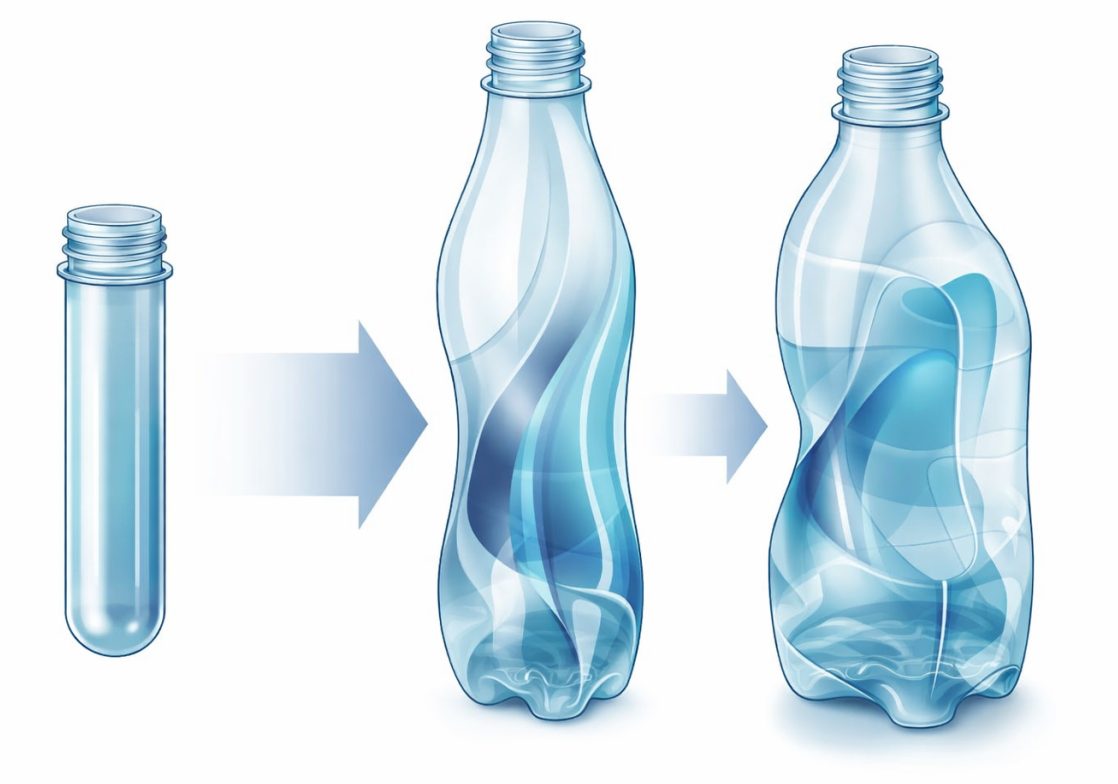

In many projects, the fastest way to regain control is not another round of parameter tweaks. It is to treat preform design and the bottle blowing process as a matched pair, then adjust the preform to feed the shape you actually want. In practice, issues caused by complex bottle shapes often become visible only when preform geometry, blow mould structure, and process settings are evaluated together, making proper blowing system alignment for complex bottle shapes a critical part of stable production.

What Makes a Bottle Shape “Complex” in PET Production

“Complex” is not a style label. It is a technical signal that material distribution and stretch behavior will not follow the easy path.

Non-Symmetric and Non-Round Bottle Geometry

Non-round designs force PET to stretch unevenly. An oval bottle, a flattened face, or a bottle with a sharp corner asks the material to travel farther in some directions than others. That change alone can create thin spots, stress marks, or uneven wall thickness distribution, even when your pet preform production looks fine on paper.

Deep Panels, Sharp Transitions, and Functional Features

Deep label panels, strong ribs, grip zones, and fast shoulder transitions can be “shape traps.” PET wants smooth stretch. When the cavity asks for a sudden turn, the plastic blow molding process may pull material away from one area and stack it in another. The result can be a bottle that passes the first check, then shows denting, whitening, or weak areas after filling and cooling.

Tight Tolerances Driven by Filling, Capping, or Labeling

Some shapes are not just cosmetic. They must register well for labeling, stay square for conveyors, or hold top load for pallet stability. If your downstream line is strict, small variations become real rejects. That is where preform-to-bottle compatibility stops being a slogan and becomes an engineering requirement.

Why Standard PET Preforms Often Fail on Complex Bottle Shapes

Once you see what “complex” means in stretch terms, the failure pattern of standard preforms becomes predictable.

Uneven Material Distribution After Blowing

Standard preforms are usually built around average stretch paths. On complex bottles, “average” is not real. Material may rush into the easy areas and starve the hard areas. You then get thin shoulders, weak corners, heavy bases, or random panel softness. It can show up as uneven wall thickness after blowing, even when you are running normal oven settings.

Narrow Process Window and Unstable Production

Complex shapes often shrink your safe range. A small shift in heating zones, a small change in preform temperature, or slight variation in pet injection conditions can push quality out of spec. Operators then chase defects by changing settings, which sometimes makes the next defect worse. That is how a narrow blowing window becomes a long-term habit.

Higher Scrap Rate and Inconsistent Bottle Performance

When the process window tightens, scrap rate rises. Some plants accept it as “the cost of an unusual bottle.” It does not have to be. In many cases, the preform is simply not feeding the cavity in a way that matches the shape.

Key Preform Design Variables That Must Be Customized

Custom PET preform solutions are not about making the preform look different. They are about controlling how the resin moves during stretch and blow.

Preform Geometry and Wall Thickness Distribution

Preform geometry is your first chance to pre-position material. If a bottle needs strength in a grip zone or a deep panel, the preform needs the right wall thickness distribution before it ever reaches the oven. The goal is not to create a “thicker preform.” It is to shift thickness where the bottle will demand it after stretching.

A practical way to think about it is this: complex bottles are rarely uniform. Your preform should not pretend they are.

L/T Ratio and Stretch Behavior

The L/T ratio influences how easily the preform can stretch without thinning too fast. If the preform is too long and too thin, the stretch behavior can become unstable, especially in hard-to-fill cavity zones. If it is too short or too thick, you may fight poor material flow and slow forming, which can create haze or surface marks. This is where PET preform design becomes a real balancing act, not a template.

Neck Finish and Support Ring Considerations

Neck finish accuracy affects capping, sealing, and handling. On complex shapes, small neck issues are amplified because the body is already harder to control. If the neck is slightly off, the bottle may still blow, but downstream problems appear. Stable neck geometry is a quiet requirement for production consistency.

Aligning Preform Customization With the Blow Mould Design

Preform changes alone do not solve complex bottle projects. You need blow molding design and preform design to agree on the stretch path.

Preform-to-Bottle Compatibility

Preform-to-bottle compatibility means the preform “wants” to become that bottle. If the bottle has a deep panel, the preform must carry enough material to fill it without pulling the rest of the bottle too thin. If the bottle has a sharp transition, the preform must stretch in a way that does not create local stress.

This is also where custom blow molding matters. In projects involving complex bottle shapes, custom blow molding is often required to match preform geometry with heating zones, stretch behavior, and final bottle performance, rather than relying on standard blowing settings.

Heating Zones and Stretch Rod Strategy

Heating zones control where the preform becomes soft first. For complex shapes, that timing matters. If one side heats faster, the bottle may lean, twist, or thin out in one region. Stretch rod motion also shapes the axial stretch path, which then affects how the material distributes radially. For complex bottles, you are not just “blowing harder.” You are guiding the plastic blow molding process.

For complex bottle projects, custom blow molding only works when preform geometry, heating zones, and stretch behavior are developed as part of integrated preform and blow mould solutions, rather than adjusted independently during trial runs.

Cost and Risk Trade-Offs in Customized Preform Solutions

Customized PET preform solutions are not always more expensive. The real question is where cost moves.

When Customization Reduces Total Production Cost

Customization often lowers total cost when it expands the process window, reduces scrap rate, and shortens the time you spend in trial-and-error. A preform that “fits” the cavity can stabilize cycle time, reduce rejects, and make output predictable. In high-volume work, those savings show up fast.

When Over-Customization Becomes a Problem

Over-customization happens when you solve a small issue by adding complexity that creates new maintenance and variation risks. You may end up with a preform that is too sensitive, a design that locks you into one bottle, or a solution that is hard to reproduce across cavities. The best custom PET preform solutions stay practical. They target the real stress points and leave everything else simple.

When to Move From Standard to Customized PET Preform Solutions

You do not need customization for every project. But there are clear signals when it is time.

Signs Your Current Preform Is Limiting Production

If you see repeated defects in the same regions, constant sensitivity to minor oven shifts, or quality that changes with small resin lot differences, your preform may be the limiting factor. Another sign is when the team relies on “tribal knowledge” to keep bottles acceptable, because the process window is too narrow to be managed calmly.

Project Types That Typically Require Custom Preforms

Non-round bottles, deep panels, heavy embossing, and bottles with strict labeling alignment often benefit from customized PET preform solutions. If the shape is complex and the line must run fast, standard parts usually reach their limit early.

Conclusion

Custom PET preform solutions for complex bottle shapes are not a design exercise for its own sake. They are a way to regain control of material distribution, stabilize stretch behavior, and make the pet bottle blowing process repeatable. When you align preform geometry with blow molding design, heating zones, and long-run stability, you turn “difficult bottles” into predictable production.

When evaluating custom PET preform solutions for complex bottles, reviewing how preform design, blow mould configuration, and long-term production stability work together is often more effective than focusing on individual components.

Where Complex Shapes Become Stable Output

HEYAN TECHNOLOGY (Foshan Heyan Precision Mold Technology Co., Ltd.) supports PET packaging projects where shape complexity and production stability must live together. The team develops and manufactures preform mould, bottle blowing mould, cap mould, and complete line supporting programs, with a focus on practical runability: cavity consistency, cooling balance, and mould stability over long cycles. For complex bottle shapes, the work is not limited to one tool. Preform geometry, wall thickness distribution targets, and blow-side requirements are treated as one chain so your trial runs are shorter and your daily output is steadier. If you care about scrap rate control, cycle time stability, and a wider process window for non-round or high-detail bottles, HEYAN TECHNOLOGY brings engineering support that stays grounded in real production conditions, not just first samples.

FAQ

Q1: How do you know when complex bottle shapes require custom PET preform solutions?

A: If the process window is tight, defects repeat in the same zones, or scrap rate keeps climbing, a standard preform may be limiting the shape.

Q2: Does custom blow molding always mean you need a new preform mould?

A: Not always. You can try blow settings and heating zones first. If preform geometry still cannot feed the cavity, a mould update is usually needed.

Q3: What is the biggest mistake in PET preform design for non-round bottles?

A: Treating a non-round bottle like a round one. That often leads to uneven wall thickness distribution and unstable output.

Q4: How does preform customization affect total production cost?

A: It can lower cost by reducing scrap rate and stabilizing production. Over-customization can add complexity and maintenance risk.

Q5: Which matters more for complex shapes: the injection molding process or the bottle blowing process?

A: Both. Injection sets material distribution in the preform. Blowing turns it into the bottle. Misalignment in either step causes defects.