Why Injection Molding Tolerances Break Down in Mass Production and How System-Level Control Restores Stability

A tolerance that looks safe on a drawing can turn messy once the line runs for days, because early parts may pass and the first shift may look great, then dimensions start to wander, gauges stop agreeing, operators chase settings that worked “yesterday,” and scrap quietly stacks up. In mass production, injection molding tolerances are not just a design target; they are a stability test, and when tolerance drift shows up, the root cause is usually not one “bad” parameter but a production system that has weak points.

What Injection Molding Tolerances Really Mean in Production

In production, tolerances mean repeatable parts across time, not one perfect sample. A single part can hit spec while the process still drifts. Real tolerance performance means the line can hold dimensions after warm-up, after a tool change, and through normal shift variation. That repeatability becomes harder when cycle time is tight, material lots change, and the plant environment shifts.

Multi-cavity work raises the bar again. In multi-cavity injection molding, you are not chasing one dimension. You are chasing the same dimension in several cavities, at the same time, with the same acceptable spread. If your project is multi-cavity, the practical side of injection molding tolerances in multi-cavity production is a useful reference for how cavity balance and repeatability shape what “good tolerance” means on the floor.

Why Tolerances Look Achievable in Trials but Fail in Mass Production

Short trials hide problems. A trial may run before thermal conditions settle. It may use one operator, one material lot, and a clean schedule. Mass production adds time, heat, variation, and human reality, which is where tolerance breakdown starts.

Here are common reasons a “good trial” turns into tolerance instability later:

-

Heat soak changes the mold’s real steady state over long runs

-

Material lots shift, viscosity moves, and fill balance follows

-

Cooling water and utilities vary as plant demand changes

-

Shift-to-shift setups drift, even with “the same settings”

-

Cavity balance changes with wear, vent condition, and contamination

If a dimension drifts steadily after a few hours, or flips after downtime, you are likely looking at stability limits, not a one-time setup error.

Process Drift Is the Primary Cause of Tolerance Breakdown

Process drift is the slow slide away from repeatability. It often comes from thermal change, pressure change, or flow change. Drift can be subtle. Parts still look fine. The deviation shows up in a gauge, then in assembly, then in complaints.

Use drift patterns to guide first checks, so troubleshooting stays disciplined instead of reactive.

| Drift Pattern (What You See) | Likely Cause | First Checks |

|---|---|---|

| Dimension drifts in one direction over hours | Thermal drift | Mold temp trend, cooling water temp, cycle time stability |

| Dimension jumps after downtime or breaks | Restart imbalance | Warm-up routine, purge practice, mold temp recovery |

| One cavity drifts while others stay OK | Cavity-to-cavity variation | Cooling balance per cavity, vent condition, gate wear |

| Random scatter shot-to-shot | Pressure or flow variation | Packing repeatability, material lot shift, restrictions |

Thermal Drift Over Long Production Runs

Heat is not stable by default. Mold temperature can creep during long runs. Melt temperature can vary with recovery behavior or heater control drift. Cooling water may change with plant demand. These shifts change shrink, and shrink changes dimensions.

A common sign is a dimension that drifts in one direction during a long run, then “resets” after downtime. That pattern often matches thermal behavior. If drift aligns with mold temperature or cooling flow changes, chasing packing settings will only hide the real cause.

Pressure and Flow Variation

Pressure variation affects how the cavity packs and how the part shrinks. If packing pressure is inconsistent, the same cavity can produce different densities shot to shot. That shows up as tolerance drift on critical fits.

Flow variation matters too. Gate conditions change over time. Material lot changes shift viscosity. Filters load. Small restrictions alter fill balance. When one cavity sees a slightly different flow path, it does not take much to create measurable spread.

Multi-Cavity Production Amplifies Small Tolerance Errors

Multi-cavity tooling is efficient, but it is unforgiving. A minor variation in a single cavity becomes a measurable range when several cavities run together. This is why cavity-to-cavity variation becomes a production headache, not a lab curiosity.

In cavity injection molding, small differences between cavities can quickly turn into measurable tolerance variation during mass production. A slight temperature offset, a small pressure loss, or a venting difference can push one cavity out of band while the others stay “fine.” That is the worst scenario because the line looks healthy until inspection catches the outlier.

Treat cavity balance as a living condition. It can drift with heat, wear, and contamination. A balance that was correct on day one may not stay correct on day thirty.

Why Adjusting One Parameter Cannot Fix Tolerance Instability

A single-parameter fix feels fast. It also fails often. Change melt temperature and viscosity shifts, which shifts fill, which shifts packing, which shifts shrink, which shifts warp, which shifts final dimensions. One adjustment can “fix” one feature while breaking another.

This is why endless tuning happens. The line moves from one temporary win to the next, and the same tolerance problem returns after warm-up or shift change. When that happens, blaming the tool or the operator rarely helps. The real issue is coordination. Injection molding tolerances are a system output, not a single-knob result.

System-Level Factors That Decide Long-Term Tolerance Stability

Stable tolerances come from stable inputs. Those inputs are not limited to the mold and the press. Long-term repeatability depends on how the full system behaves, including auxiliary equipment and production conditions. This is where many projects lose control quietly.

One practical reminder fits here: if early sourcing focuses too much on injection molding mold cost, the plan can miss the system stability needed to hold tight tolerances in mass production. The cheapest tool is rarely cheap once rework, downtime, and sorting begin.

Mold Design and Thermal Control Integration

Mold design influences thermal behavior. Cooling layout and heat transfer paths shape how fast the tool reaches steady state and how well it holds it. If cooling is uneven, shrink varies across the part and across cavities, and tolerance stability suffers.

Tool condition matters too. A vent that clogs can shift fill behavior, and a gate that wears can shift pressure. These are slow changes, and they often show up first as tolerance drift.

Injection Machine Consistency and Repeatability

Repeatability is daily behavior. Shot-to-shot variation, speed consistency, and clamp stability all influence dimensions. If recovery time varies, melt condition varies. If injection speed varies, shear varies. Those changes ripple into shrink and final size.

Even with a strong machine, stability depends on how it is run. A line that needs constant manual rescues will struggle with tight tolerances.

Auxiliary Systems That Are Often Ignored

Auxiliaries can make or break tolerance stability. Cooling water temperature swings move shrink. Air supply issues affect valve timing on automated actions. Power quality issues cause heater variation. Plant environment matters too, especially for conditioning and measurement timing.

A small, real-world annoyance often appears: the line runs great until plant demand changes, then a “mystery” drift appears. It is not mystery. It is input variation.

How System-Level Control Restores Tolerance Stability

When tolerances break down in mass production, the recovery plan should not be “more tuning.” It should be better control of the system that creates the part. System-level control means coordinated control of the mold, the machine, the auxiliaries, and the production conditions that shape repeatability.

That is where system-level control in injection molding fits. It shifts the focus from chasing symptoms to stabilizing inputs. In practical terms, it means stable thermal management, consistent pressure behavior, predictable cooling, and coordinated process control that holds through long runs. It also means fewer “hero adjustments” that only one person can do.

If tolerance targets matter because parts must assemble, seal, or align, an injection molding system approach is not a nice extra. It is the path to production stability.

When Tight Tolerances Are Realistic and When They Are Not

Tight tolerances are realistic when the design supports them, the material behavior is predictable, and the process inputs stay stable. They become unrealistic when geometry magnifies shrink effects, when material behavior varies widely, or when the line inputs drift.

Think of a tolerance target as a contract between design and production. If production cannot hold steady inputs, the contract fails. In that case, either change the system, change the design, or change the expectation. Picking the honest option early saves money later and avoids repeated “fixes” that never stick.

Conclusion

Injection molding tolerances break down in mass production because stability is harder than it looks. Trials prove a moment. Production tests time. Drift comes from heat, pressure, flow, and cavity balance, and those factors interact. A lasting fix comes from system-level control, where the whole line supports repeatable output instead of constant tuning.

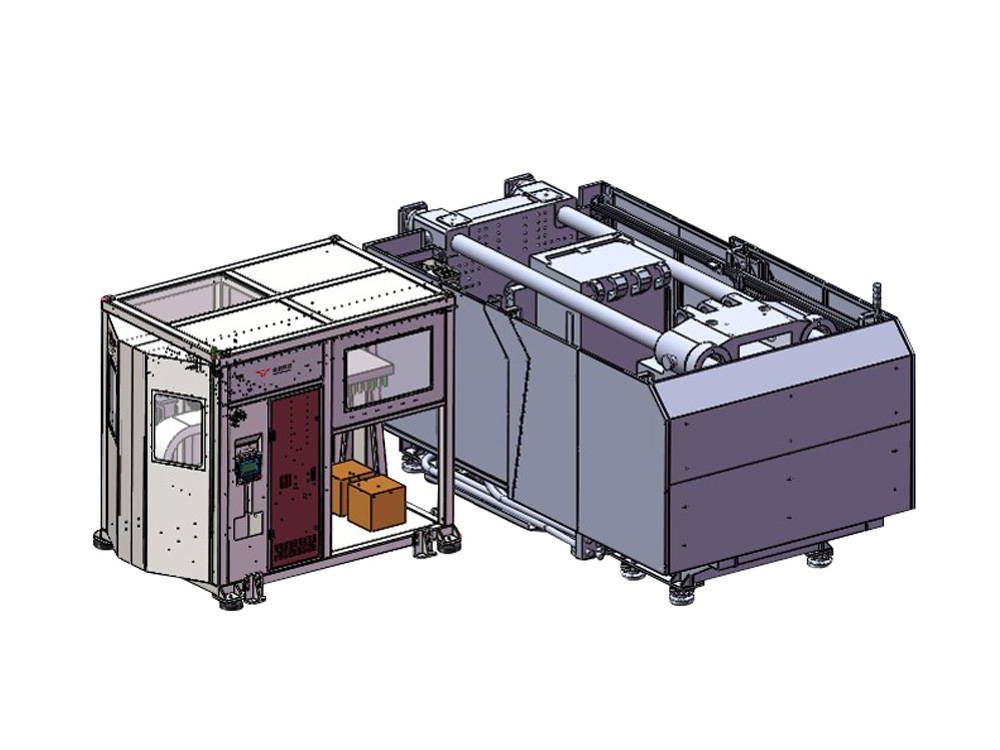

Precision Support for Tolerance-Critical Production

HEYAN TECHNOLOGY (Foshan Heyan Precision Mold Technology Co., Ltd.) supports injection molding projects where repeatability matters as much as speed. You get precision tooling and practical engineering support aimed at stable mass production, not just a successful trial. The technical team focuses on the real drivers behind tolerance stability, including cavity balance, thermal control, process repeatability, and the supporting systems that keep output consistent over long runs. When a project needs more than a mold handoff, HEYAN TECHNOLOGY provides system-oriented support that helps align equipment selection, auxiliary planning, and production conditions with tolerance targets, so dimension control stays steady across shifts and batches.

FAQ

Q1: Why do injection molding tolerances drift after several hours, not right away?

A: Heat and flow conditions change as the line reaches steady state. Cooling water, mold temperature, and packing behavior can slowly shift, then dimensions follow.

Q2: Is multi-cavity injection molding always harder for tolerance control?

A: In practice, yes. Small cavity differences add up, and one cavity can drift while others look fine, which makes the tolerance range harder to hold.

Q3: Should the first fix be packing pressure or mold temperature?

A: Start by checking stability patterns. If drift follows thermal behavior, address thermal control first. Packing changes can mask the issue and make it return later.

Q4: What is a quick sign the issue is system-level, not one setting?

A: The fix only works for one shift, or it works until warm-up, or results change with plant conditions. Those patterns point to input drift across the system.

Q5: How do you stop endless tuning and get stable tolerances?

A: Treat tolerance as a system output. Stabilize key inputs first, then lock a repeatable window. That is where system-level control makes the biggest difference.