Why Manufacturers Choose Multi-Cavity Injection Molding to Scale Production and Cut Cost

When orders keep growing and delivery dates stay tight, it is hard to keep up with demand with only single-cavity tools. You feel pressure from customers, because they ask for faster delivery. At the same time your plant needs to keep the cost for each part low. In this kind of situation, multi cavity molding often becomes a simple and direct way to raise output without losing control of part quality.

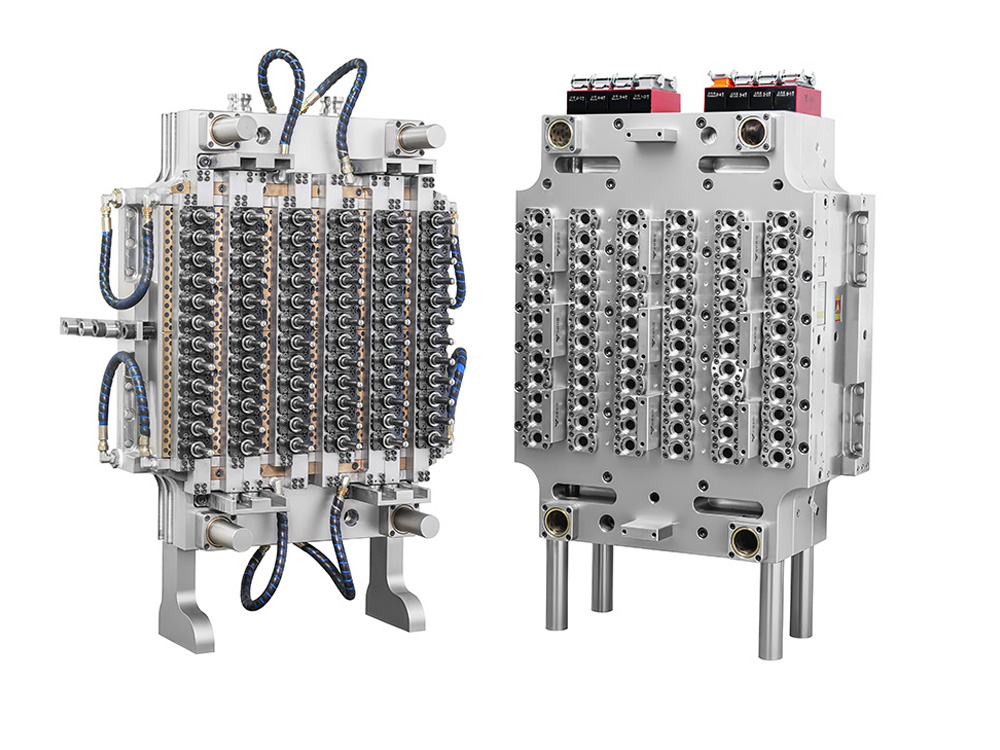

What Is Multi-Cavity Injection Molding?

Multi cavity molding means using one mold with several cavities that all make the same part in each cycle. Instead of getting one piece every shot, you may get 4, 8, 16, or even more pieces at once. The basic injection molding steps do not change. You still close the mold, inject, cool, and open it. What really changes is how quickly you can reach your daily production target.

When you move from a single cavity mold to a multi cavity mold, the whole way you plan production starts to change. You can use one mold for one part and still reach high volume. You do not need to run many tools in parallel or keep changing molds on the same press through the day.

Basic Concept and Why Cavity Count Matters

Each cavity in the mold is like a small copy of the final part. More cavities mean more parts per shot. If your current tool makes 1,000 parts per day, a well designed 8-cavity tool can push that number much higher without buying new presses. Of course, the best cavity count depends on machine size, part size, and order volume. Even so, the core idea stays clear: more good pieces in each cycle over the same working time.

How Multi-Cavity Injection Molding Helps You Scale Production?

When people talk about scaling production, they often think of buying extra machines or adding night shifts. Multi cavity mold gives you another path. You can increase output on the presses you already own. This makes planning easier and keeps the workshop cleaner and more simple.

More Parts per Cycle and Higher Daily Output

The most direct benefit is easy to see. More cavities give more parts in one shot. If one cycle gives you 8 parts instead of 1, daily output can jump several times as long as the cycle time stays close to your original value. This is what people mean when they talk about high-output multi cavity injection molding. You use one well balanced tool to handle large orders instead of fighting with many small molds and setups.

Cycle Time Reduction With Better Cooling Design

Cycle time decides how many cycles you can run per hour. In multi cavity molding, cooling design is one of the main points to watch. If cooling channels go to the right places and remove heat in a steady way, parts can come out faster without warpage or short shots. Small changes in water channel layout can often cut a few seconds from the cycle. Over weeks and months, that difference turns into many extra boxes of parts.

Balanced Filling and Stable Quality

With several cavities, you want the plastic to reach each one in almost the same way. A balanced runner layout helps keep fill time and pressure close between cavities. When filling stays even, you see fewer size changes, less flash, and fewer parts that need sorting. This kind of steady behavior is important if you plan to run the mold every day and push production close to the planned output.

How Multi-Cavity Injection Molding Helps Cut Unit Cost?

Higher output is only one side of the story. In most factories, the real decision comes from total cost per part. A multi cavity mold usually has a higher upfront price, but over time it can pay back that cost. It does this through lower labor cost, fewer machine hours, and less scrap.

Lower Labor Cost and Fewer Machine Hours

If one press with a multi cavity tool can make as many parts as several presses with single cavity tools, you need fewer operators and fewer setups. You also free machine hours for other parts. In simple words, each hour of machine time gives you more usable pieces. This is one way multi cavity molding helps you cut the cost per part without changing the material or the final design.

Less Energy Use per Part

Every molding cycle uses power for heaters, the clamp, and the injection unit. When one shot gives you more pieces, that power gets spread across more parts. Over a long run this can bring a clear drop in energy cost, especially for thin-wall or high-speed parts. Many factories look for quiet ways to lower energy bills. A smart choice of multi cavity tooling for large-volume production is one way to move in that direction without big changes to the whole plant.

Reduced Scrap and Rework

A steady multi cavity mold with good cavity balance tends to give repeatable parts. When the cavities behave in a similar way, you need fewer corrections and see fewer rejects. Less scrap means less material waste and less time spent on rework. This may not look exciting on a chart, but in daily work it often makes the shift easier and cuts hidden cost that comes from sorting and re-running bad parts.

When Should You Choose a Multi-Cavity Mold?

Not every part needs many cavities. Some projects are low volume or change often, so a single cavity tool is enough and more flexible. But for some product types, a multi cavity mold is almost the normal choice rather than a special option.

Best for High-Volume or Fast-Moving Products

Caps, closures, many daily-use plastic pieces, and some packaging parts often run in very large quantities. If you plan to ship these parts every week, multi cavity injection molding gives you a way to keep up with orders without filling the whole workshop with different molds. For fast-moving consumer goods, steady output can be as important as the price written on the quote.

When Tooling Cost Can Be Recovered Quickly

A multi cavity mold costs more to build than a simple tool, but the payback can be fast when volume is high. If a new tool can cut the unit cost by a few cents and raise daily output, you may recover the tooling fee in a much shorter time than you first think. It helps to sit down with real numbers. Look at expected volume, current cost, and the extra pieces per day you can ship with a higher cavity count. Once you see these numbers together, the decision often becomes clearer.

When You Need Shorter Lead Time

Some buyers choose suppliers because they can react quickly to big orders or sudden changes in plan. When you have advanced multi cavity mold solutions in your plant, you can accept tight lead times with more confidence. You do not need to say yes first and then worry about capacity in the background. Instead, you already know which tools can handle a sudden jump in demand.

Key Factors To Check Before Investing in a Multi-Cavity Mold

Before you confirm a new tool, there are a few basic checks that can save you trouble later. A mold may look fine in a drawing, but it also has to fit your machines and your way of running the line day after day.

Machine Size and Clamping Force

Higher cavity counts need more clamp force and often a larger shot size. You should check whether your existing presses can handle the mold in a safe way. If the machine runs close to its limit all the time, small changes in material or settings can cause defects. A simple check on clamp force and shot volume in the early stage can help you avoid this kind of problem.

Runner Layout and Gate Balance

Runner layout tells the plastic where to go and in what order the cavities fill. For multi cavity tools, a balanced layout matters a lot. Poor balance can lead to some cavities flashing while others are short. It is worth spending time with your supplier to review the runner and gate plan, even if it means a few extra calls or emails at the start of the project.

Cooling Layout and Mold Steel

Cooling channels and mold steel have a strong effect on both cycle time and mold life. Good cooling layout helps you keep cycles short without warpage. Proper steel choice helps the mold stand up to long runs, glass-filled materials, or higher molding temperatures. It is better to talk about these points early than to regret a weak choice after the first busy season when the mold must run all day.

Why Many Manufacturers Work With a Professional Supplier

As cavity count goes up, small design mistakes can turn into daily problems on the shop floor. This is why many buyers prefer to work with a reliable multi cavity mold supplier instead of treating the mold like a simple one-time purchase. A good partner looks at your part drawing, volume plan, and machine list. Then the team suggests a cavity count and mold structure that fit your real situation, not just a clean 3D model.

Support From Design To Stable Production

Support does not stop at design. Some suppliers also help during first mold trials, with start-up settings, and with improvements based on the first few real batches. This type of help makes it easier for you to reach your goals for both output and cost. It also reduces the risk that the tool sits still because the process is hard to tune or the team is not sure where to start.

Why Choose HEYAN TECHNOLOGY for Multi-Cavity Projects

HEYAN TECHNOLOGY, Foshan Heyan Precision Mold Technology Co., Ltd., focuses on precision molds for preforms, caps, and other high-volume plastic parts. The company runs a modern plant in Foshan with CNC machining, EDM, grinding, and measuring machines that fit complex multi cavity tools. Project and engineering teams follow each mold from drawing review through mold trial, so the final tool matches real production needs instead of just meeting basic shape data. For buyers who care about steady output, long mold life, and clear talk during the whole project, HEYAN TECHNOLOGY offers practical support for multi cavity injection molding work.

FAQ

Q1: When is multi cavity injection molding better than a single cavity mold?

A: It is a better choice when your part has a stable design and high volume. If you need to ship large orders often, a multi cavity tool lets you make more parts every cycle and cut cost per part over time.

Q2: How many cavities should a multi cavity mold have for my project?

A: The right number depends on part size, machine size, and your target volume. You can start with a rough idea, then talk with your mold supplier to match cavity count with clamp force, shot size, and your daily production plan.

Q3: Does multi cavity injection molding always mean shorter cycle time?

A: Not always. Cycle time still depends on cooling and part thickness. But when cooling is planned well, a multi cavity tool can give many more parts per hour even if the cycle time stays close to your current value.

Q4: Is a multi cavity mold only worth it for very large orders?

A: It is most common for large or long-term orders, but some medium-size projects can also justify it. If the extra cavities cut labor and machine time enough, the mold cost may be recovered faster than you expect.

Q5: What should you check before ordering a multi cavity injection mold?

A: You should check machine size, clamp force, and shot volume. You should also review runner balance, cooling layout, and expected volume with your supplier. A short review at this stage helps you avoid surprises when the mold reaches your plant and begins real production.